Screw Powder Filling Machine Features:

1. High efficiency: The Cohomachine conveyor belt screw packing machine can perform high-speed automatic filling, which significantly increases production efficiency.

2. Precise measurement: The machine is equipped with a high-precision sensor that can measure the exact amount of powder that needs to be packaged, with a deviation of just a few grams.

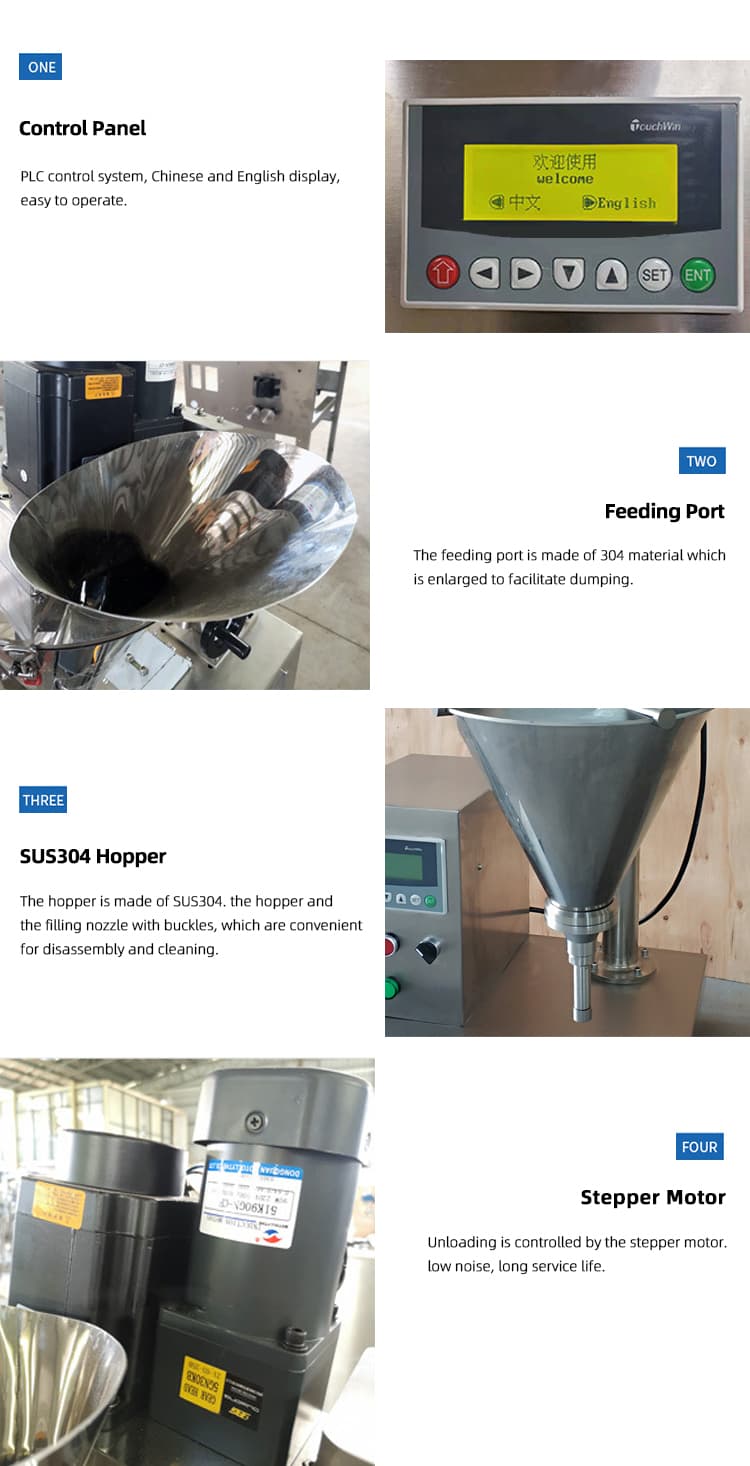

3. Easy to operate: The machine's user-friendly interface and design make it easy to operate and maintain.

4. Sturdy construction: The equipment is made of high-quality materials, ensuring a long lifespan and efficient operation.

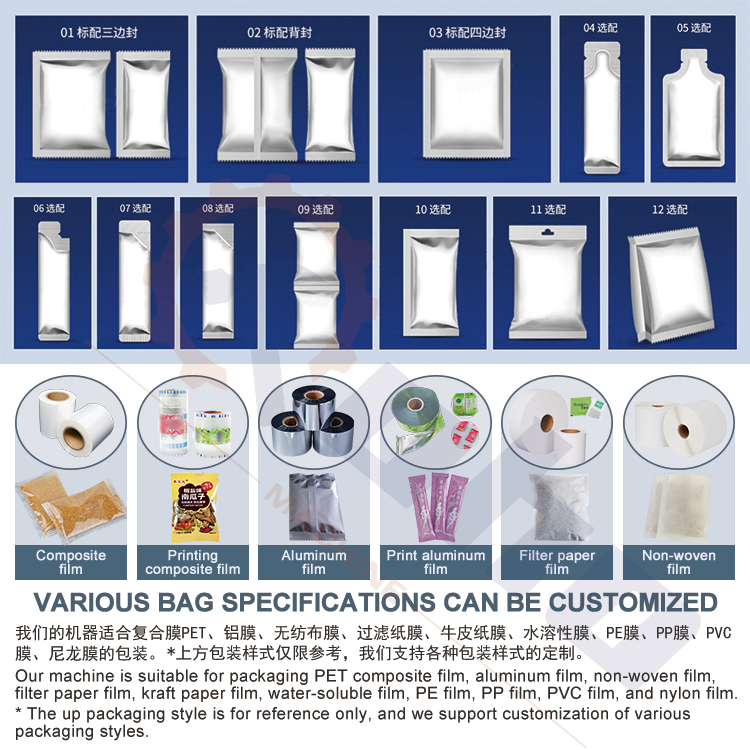

5. Wide application: This machine is suitable for packaging many kinds of powder materials, such as Milk Powder, wheat flour, and other related products.

The CohoMachine screw powder filling machine is a fully automatic quantitative powder filling machine that can be used for all kinds of powder and mixed powder-like material weighing filling, such as: fertilizers, additives, flour, milk powder, coffee powder, washing powder, solid drink, sugar, monosodium glutemate, condiments (such as spicy fresh), natural flavoring , enzymes, feed powder (powder, superfine powder), mixing quantitative powder-like material filling.. This packing machine is a highly efficient and precise machine capable of accurately measuring and packaging powdered products,making it an ideal choice for manufacturers who require high-quality packaging solutions.

Filling Machine Features:

1. This powder filling machine is integrated with machine, electricity, light and instrument. It is controlled by single chip computer. It has the functions of automatic quantification, automatic filling, automatic adjustment of measurement error and so on.

2. Stepping motor and electronic weighing technology, fast speed and high precision.

3. The same quantitative packaging machine can be packed 1kg-15kg by adjusting and replacing filling parts of different specifications with the keyboard of electronic scale.

4. Errors caused by material specific gravity and material level change can be automatically tracked and corrected.

The filling speed of the machine will change due to the filling volume and the viscosity of the material.

1. If there is a machine problem within 1 year of delivery,we can provide free spare parts replacement

2. Support returns within 2 days after payment,and cannot be returned after delivery

3. English version user guide manuel and video

4. Exclusive after sale customer service

5. Before shipment, the machines have been successfully tested

6. Support Certifications,CE certification,UL certification,ISO9000

7. Respond Rate 100%,During working hours,the response time is less than 10 minutes

Scan To Wechat