Automatic Screw Powder Filling Machine Features:

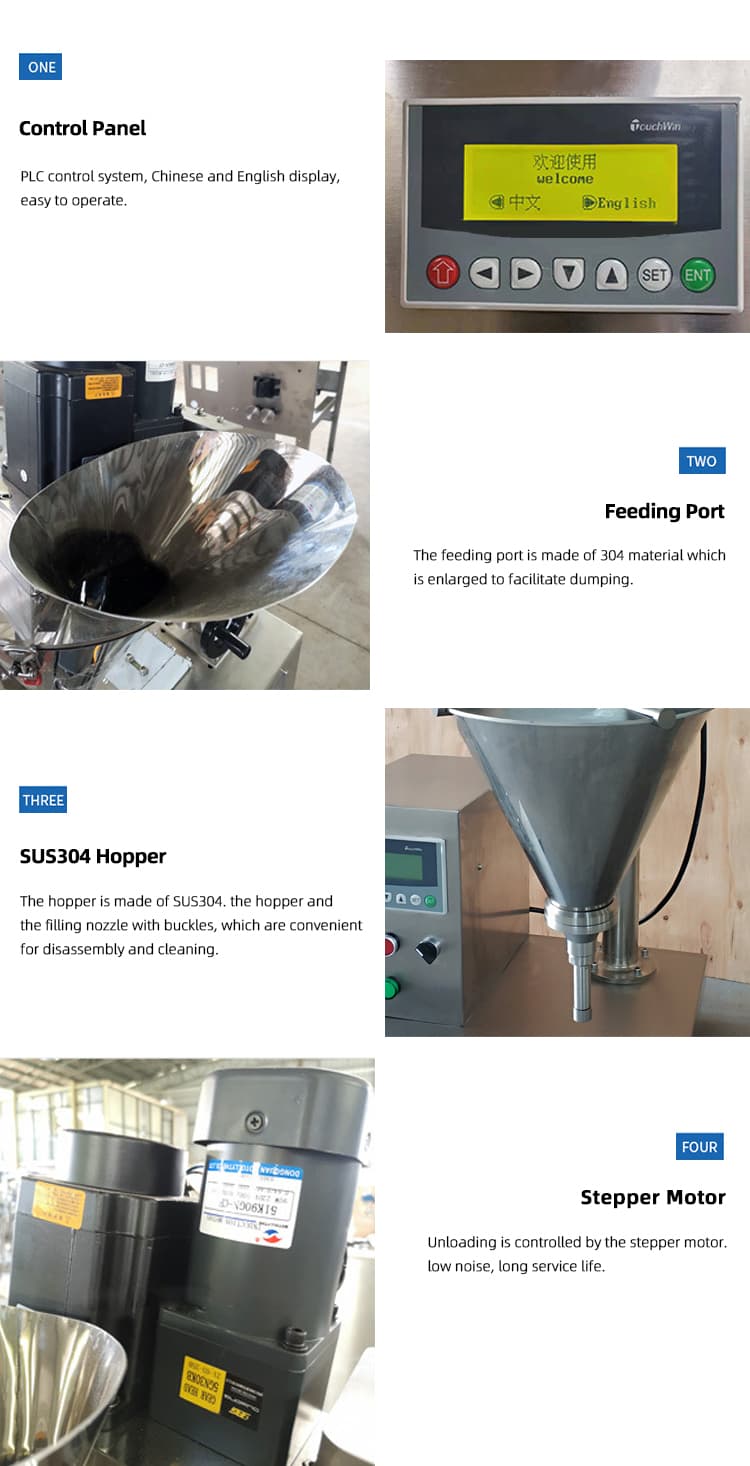

1. The machine is made of stainless steel, and the transparent hopper can be opened, so the running status of the material can be seen at a glance, and it can be easily disassembled and washed without tools.

2. The parts that are often disassembled are all connected by quick-release clamps.

3. The stirring motor adopts a maintenance-free, noiseless China-made gear reduction motor, which runs silently.

4. The feeding motor adopts a servo motor to drive the screw, which has the advantages of not easy to

wear, accurate positioning, adjustable speed and stable performance.

5. PLC control, English touch screen operation, clearly display the working status, operation instructions, fault status and production statistics, etc., the operation is simple and intuitive. It has the advantages of stable work, anti-interference and high weighing accuracy.

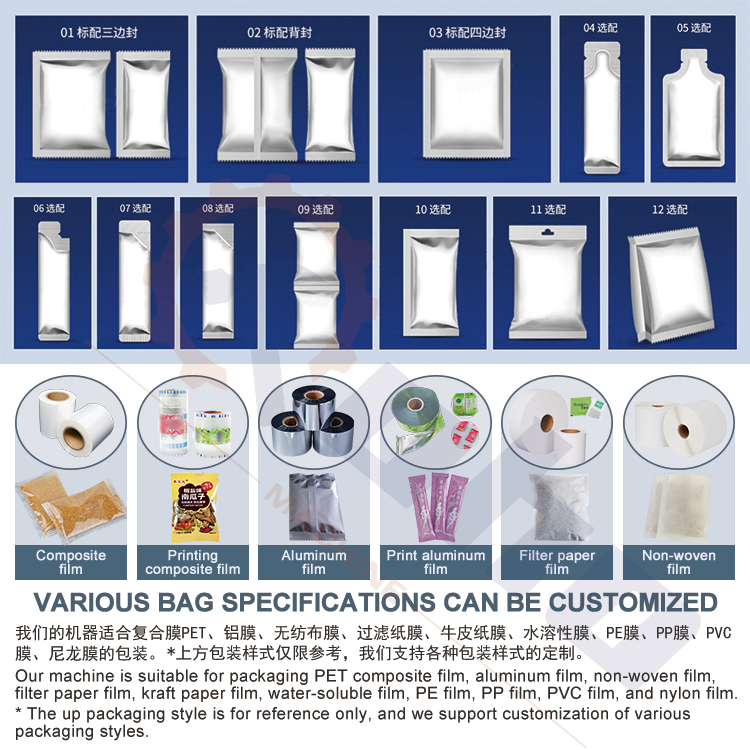

6. Adopt screw feeding and replace the screw accessories, which can be used for various materials such as ultra-fine powder to small particles.

7. With lifting function, according to different sizes of bottles, the height of the conveyor belt and the height of the feeding screw can be adjusted.

The CohoMachine screw powder filling machine is a fully automatic quantitative powder filling machine that can be used for all kinds of powder and mixed powder-like material weighing filling, such as: fertilizers, additives, flour, milk powder, coffee powder, washing powder, solid drink, sugar, monosodium glutemate, condiments (such as spicy fresh), natural flavoring , enzymes, feed powder (powder, superfine powder), mixing quantitative powder-like material filling.. This packing machine is a highly efficient and precise machine capable of accurately measuring and packaging powdered products,making it an ideal choice for manufacturers who require high-quality packaging solutions.

This machine is composed of powder filling head, chain plate conveyor belt and positioning device, which can complete the automatic positioning, filling and metering of bottles and jars. Servo motor, PLC touch screen control, easy operation and high stability. According to the different needs of different materials, dust collection devices and leak-proof devices can be added. It can form a complete filling line with bottle unscrambler, capping machine, labeling machine, etc.

The filling speed of the machine will change due to the filling volume and the viscosity of the material.

1. If there is a machine problem within 1 year of delivery,we can provide free spare parts replacement

2. Support returns within 2 days after payment,and cannot be returned after delivery

3. English version user guide manuel and video

4. Exclusive after sale customer service

5. Before shipment, the machines have been successfully tested

6. Support Certifications,CE certification,UL certification,ISO9000

7. Respond Rate 100%,During working hours,the response time is less than 10 minutes

Scan To Wechat