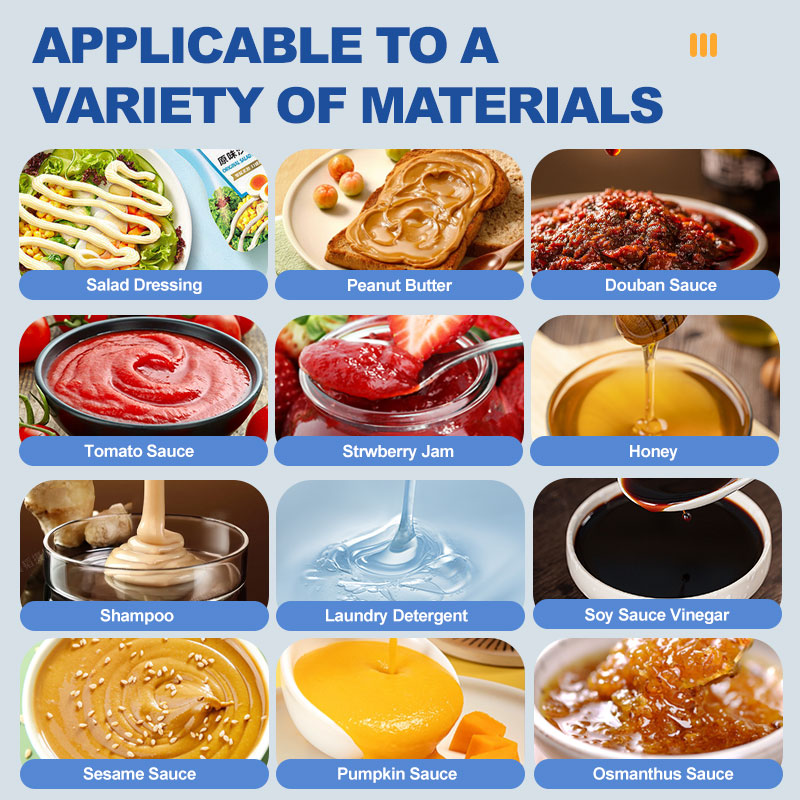

The automatic single-station bag machine is a pre-made bag automation equipment which is professionally applied to the requirements of packaging.Through a multi-station to complete a series of actions such as bagging, opening, printing, filling, and mouth of the bag, it is suitable for various particles, liquids,paste sauce,powders, powders and other materials. It is widely used in food,chemical, hardware, toys and other industries. It can be used with various filling devices such as screw scales,linear scales,tipping bucket,measuring cup,filling machineand combination scales.

Automatic paste doypack packaging machine applications:

The Automatic Peas Doypack Bag Filling Sealing Packing Machine is an automatic equipment specially used for packaging prefabricated bags with high appearance. It completes a series of actions such as opening, printing, filling and sealing of packaging bags through three stations. All kinds of granular, liquid, flake, powdery materials. It is widely used in food, medicine, beverage, chemical industry, agriculture, hardware and other industries.

1. The cup volume packaging machine can automatically complete the products of fasteners conveying, measuring, filling, bag making, date printing, heat sealing and cutting etc.

2. Stepper motor driving system is adopted in the packaging machine.

3. To ensure the same length of each bag, high sensitive electro-optical sensor system is provide to the realize automatic a lignment on the packing film.

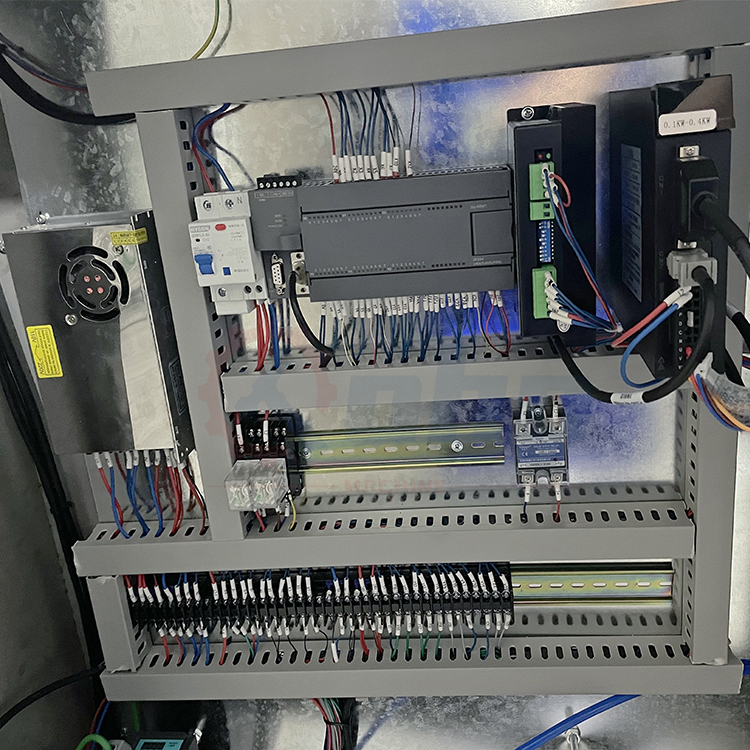

4. The packaing machine is equuipped with a computer control system.

5. We have installed constant temperture heating system ensuring stable temperture and keep temperature is +/-1°c.

6. The electroic and pneumatic components of the machine are all supplied by reliable supplier copperating with us for several years, which can ensure the quality of machine and save the cost of purchese meantime.

7. The bag size and packaging number can be customized by customers.

Multi-function Packaging Machine has many aliases:

1. daypack packaging machine 2. Coffee packaging machine 3. Paste packaging machine 4. Premade Bag Packing Machine 5. Sugar packaging machine 6. Washing and packaging machine 7. Granular packaging machine 8. Powder packaging machine, etc

Machine advantage:

1. The machine adopts high precision servo film transport system, PLC Program Control, developed touchable Human-machine Interface of Advanced Automatic Positioning, Photoelectric Tracking, Digital Temperature Control,etc.

2. Operation is more Simple, perfect. It is the first choice of food packaging industry to Improve the production efficiency,

reduce Labor Intensity, improve the grade of packaging equipment.

3. Transverse and longitudinal sealing Temperature Control independently, suitable for PE/polyethylene, PE/aluminum

plating,pet/PE, pp, and other heat-ealing packaging materials, etc.

4. It completes the whole procedure of filling, measuring, bagging, date printing, charging(exhausting), product out-putting automatically.

5. High precision, high efficiency without crash the materials.

6. Packaging style diversified, back sealing, gusset bag, continuous bags, punching, etc.

7. Work environment quiet, low noise, saving energy.

8. A complete set of equipment is economical.

1、puffed food: host + platform + combination according to hoist

2、powder: host + screw hoist + screw said

3、grain: host + screw hoist + screw said (tiny particles)

Host + platform + combination hoist said (large particle)

4、sour pickled cabbage: host + hoist + pickles machine filling machine (liquid are used,can choose) Host + platform + combination according to hoist + filling machine (liquid are used,can choose)

5、pickle: host + pickles machine + promotion + filling machine, filling machine (liquid are used,can choose) Host cup + contraction hoisting machine, filling machine and filling machine (liquid are used,can choose)

6、pickles: host + platform + electronic scale hoist filling machine Host + bowl type hoisting machine, filling machine (semi-automatic, artificial feeding) (this form a complete set for the two kinds of material mixing, two feeding, example: pickled peppers lotus root zone,etc.)

7、liquid, paste, host machine+ filling machine(this one suitable)

8、bag of bag: host + damper winding machine

If you need more product information, please contact the merchant.

1. If there is a machine problem within 1 year of delivery,we can provide free spare parts replacement

2. Support returns within 2 days after payment,and cannot be returned after delivery.

3. English version user guide manuel and video

4. Exclusive after sale customer service

5. Before shipment, the machines have been successfully tested.

6. Support Certifications,CE certification,UL certification,ISO9000

7. Respond Rate 100%,During working hours,the response time is less than 10 minutes.

Scan To Wechat